Compare Products

Geo-Form EPDM Rubber Alloy vs. HDPE Geomembrane Lining

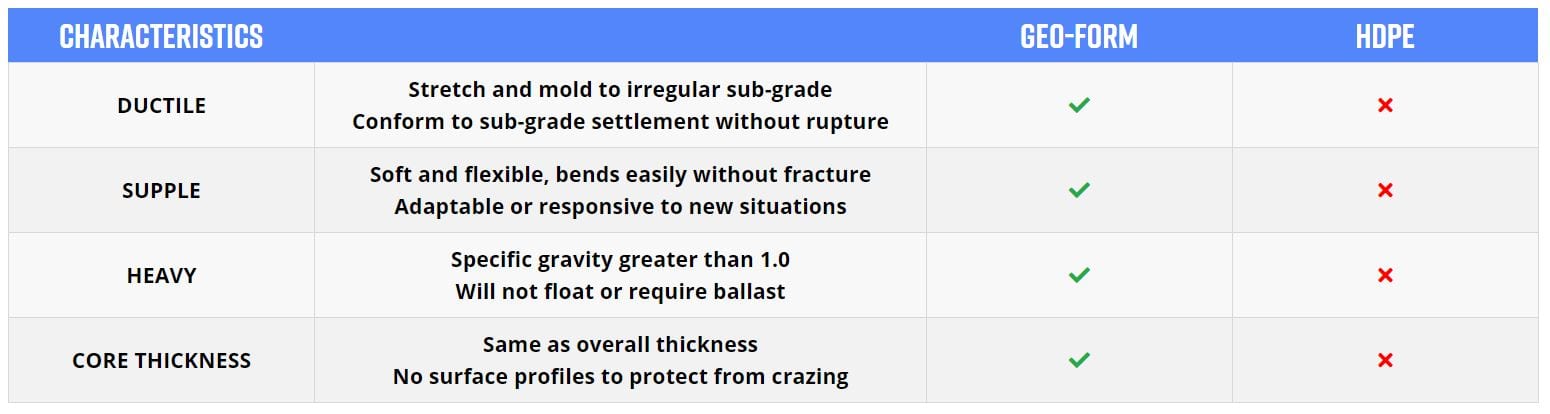

In the absence of a better option, HDPE has been specified in applications where “high” chemical resistance is not required. Now, with many years of proven performance, Geo-Form offers an alternate solution. The chart below shows the advantages of EPDM Rubber Alloy lining when compared to HDPE.

"HDPE provides good chemical resistance and toughness, but is a semi-crystalline material with a relatively low ductility that has difficulties conforming to uneven subgrades and movement. Thicker HDPE liners are also more rigid and difficult to handle and weld."

Higher Ground Consulting Report – “Performance Analysis of Engineered Liner Systems Used to Store Saline Fluids in the Canadian Oil and Gas Industry: Physical and Environmental Influences” prepared for Petroleum Technology Alliance Canada

| Characteristics | Geo-Form | HDPE | |

|---|---|---|---|

| DUCTILE | Stretch and mold to irregular sub-grade Conform to sub-grade settlement without rupture | ||

| SUPPLE | Soft and flexible, bends easily without fracture Adaptable or responsive to new situations | ||

| HEAVY | Specific gravity greater than 1.0 Will not float or require ballast | ||

| CORE THICKNESS | Same as overall thickness No surface profiles to protect from crazing |

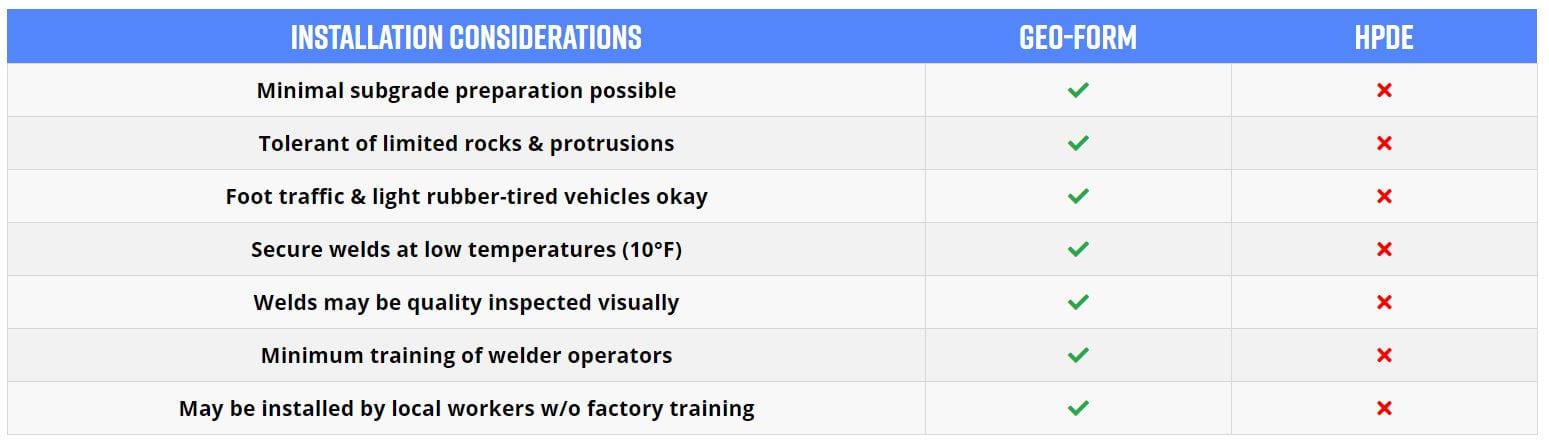

| Installation Considerations | Geo-Form | HPDE |

|---|---|---|

| Minimal subgrade preparation possible | ||

| Tolerant of limited rocks & protrusions | ||

| Foot traffic & light rubber-tired vehicles okay | ||

| Secure welds at low temperatures (10°F) | ||

| Welds may be quality inspected visually | ||

| Minimum training of welder operators | ||

| May be installed by local workers w/o factory training |

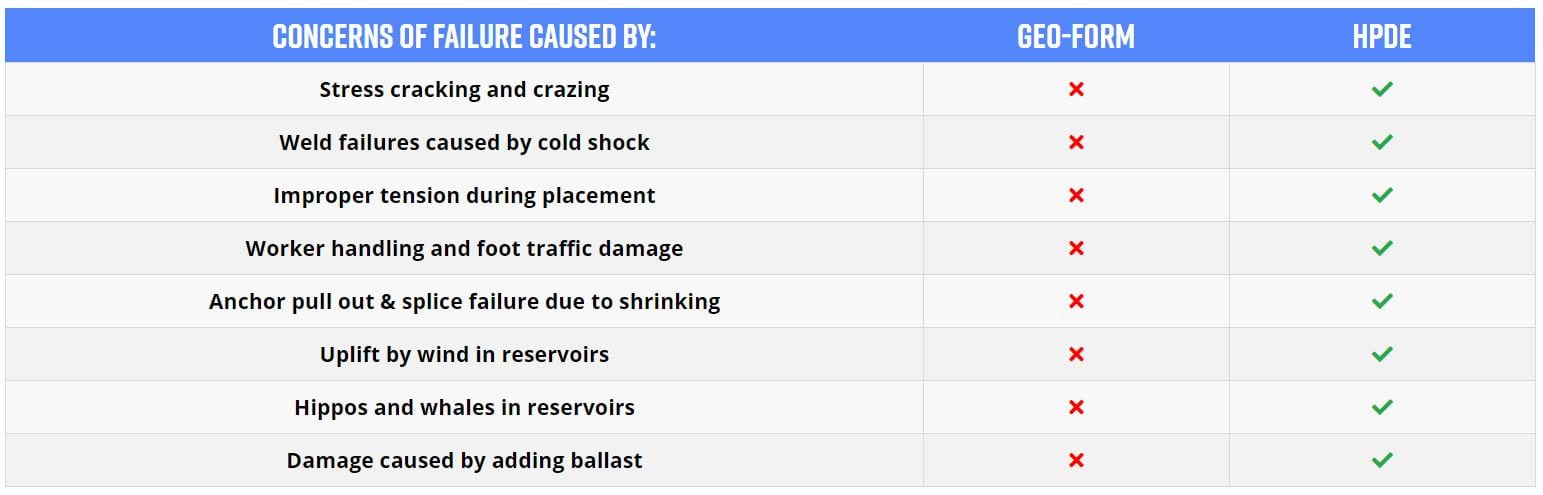

| Concerns of Failure Caused By: | Geo-Form | HPDE |

|---|---|---|

| Stress cracking and crazing | ||

| Weld failures caused by cold shock | ||

| Improper tension during placement | ||

| Worker handling and foot traffic damage | ||

| Anchor pull out & splice failure due to shrinking | ||

| Uplift by wind in reservoirs | ||

| Hippos and whales in reservoirs | ||

| Damage caused by adding ballast |

Is the Geo-Form Geomembrane Right for Your Project?

There are many variables to consider when determining if a lining is resistant to a chemical, solvent or petroleum product; life expectancy, temperatures and the level of concentration. Please contact us with the specific chemical resistance requirements of the project and we will advise if Geo-Form should be considered.

All Geo-Form Geomembrane Products are Custom Made and Built to Last

Applications

Because Geo-Form is made of weather and U/V resistant polymers, it's an ideal solution for any lining project where long life expectancy is required.

All Our Liners are Made 100% in the U.S.A.

Our Midwest Manufacturing Facility is ISO Certified

We Serve Clients All Over the World